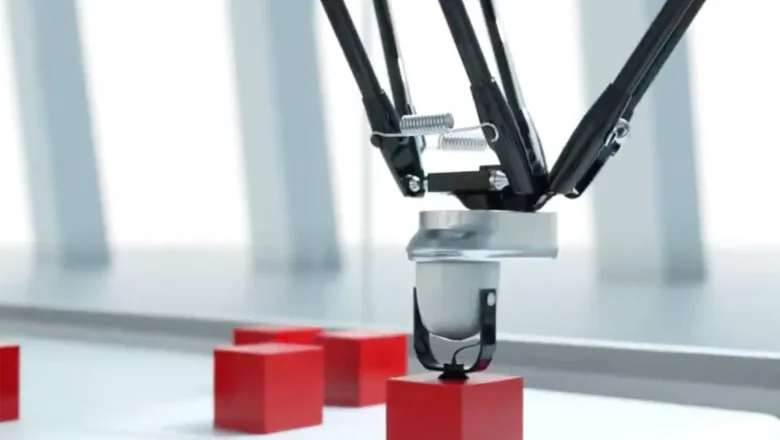

When it comes to filling machines, there are two key designs – rotary and linear. The principal task involves filling receptacles with a precise volume of liquids, which are of different viscosities and include both still and carbonated beverages. Simple dispensing systems are just as possible as the optimization of position, pressure and speed, all the way through to synchronized and interpolated movements.

Your requirement

- Exact positioning for precise dispensing

- Optimization of motion profiles

- Fast, easy product switchover

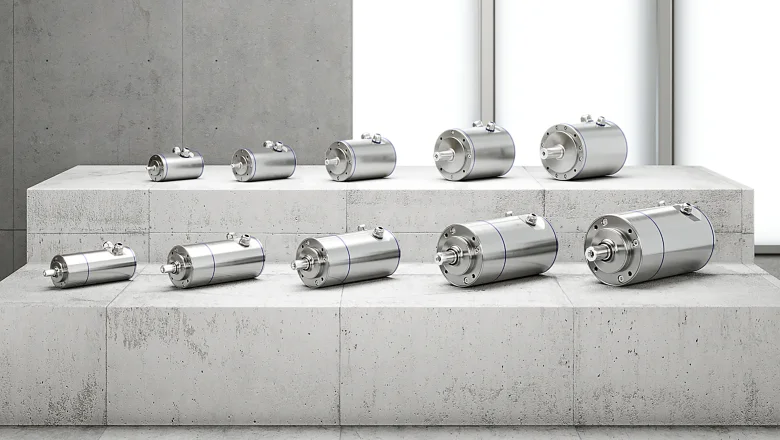

- Excellent hygiene and cleanability