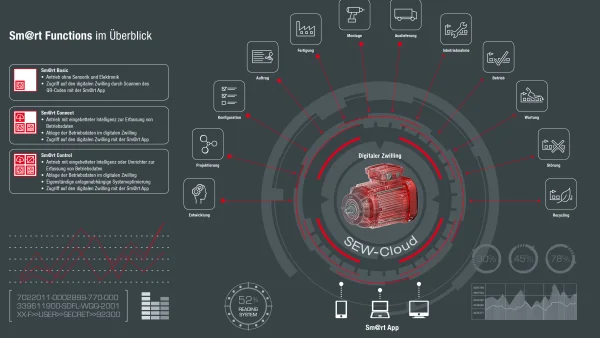

One of the basic tenets of Industry 4.0 is that all of the participants are to be networked. This is made possible by products and components with embedded systems that are capable of collecting data and communicating with one another to produce networks. This opens up entirely new possibilities. SEW EURODRIVE has been investigating what intelligent, networked products for the factory of the future might look like.

The product idea "Smart Product" is an impressive demonstration of the value of the data that is generated at every phase of the product life cycle. For example, configuration data can be saved to a component to eliminate manual configuration procedures and speed up the startup process. Or runtime data from the operation of the component can be recorded in order to improve the product or schedule predictive maintenance operations.

Three different expansion stages are in development.

- Sm@rtBasic is a drive without any sensor technology or electronics. A QR code allows access to the drive's digital twin, which contains all the important information about the drive as delivered. This SEW-EURODRIVE app provides the user with useful product and order data, including:

- Brief instructions for the most common maintenance and startup procedures

- Documentation of work performed in the drive's digital twin

- Simple identification of the drive by means of a QR code

- One-click ordering of spare parts as necessary

- Configuration-specific overview of dimensions

- Optimized service through product service record-keeping

- Simple, easy and quick product selection

- Custom-tailored suggestions for standardization

- The Sm@rtConnect drive is equipped with sensor technology and electronics for measured value acquisition, allowing the data to be recorded in its digital twin and made available for analysis.

- The Sm@rtControl feature has remote access to the drive electronics for gathering measurement data or to the associated inverter.

Your added values

- Simplified product identification with the Sm@rt App?by scanning the QR code

- Brief instructions for product- and order-specific installation and commissioning steps

- Online recording of operating parameters

- Independent plant-dependent system optimization

- Improved planning of maintenance and repair measures

- Convenient ordering of spare parts via Sm@rt App

- Documentation of the product history in the digital twin enables an optimized service